Using Float Switches for High or Low Level Alarm Indication

Details

In many applications the actual liquid level of a tank may vary within a certain range all the time with no particular action needed on the part of the attendant or owner – unless a failure occurs in the operation and the level goes dangerously high or low. A float switch installed at the high and low level points will eliminate the danger of unwanted high or low level conditions. In many cases, this has proved to be a very good example of a small investment paying off big-time. You can set up the float switch to automatically stop the operation at the point deemed critical and prevent spills and equipment failures. Our single level float switches can be mounted as both high and low level devices. These simple switches are then wired to sound an alarm or send a signal to a process controller or cut power to valves and pumps through relays.

Common Applications

- Low Water Conditions

- Heater Protection

- Leak Detection

- Overfill Warning

- Spill Prevention

How does it work…

When the liquid level in the tank reaches the float switch, it pushes the float up. A magnet located inside of the float then causes the contacts of the internal reed switch located inside of the stem to close. When the contacts close it completes the circuit connecting power to the alarm. It works the same way for low level alarms, when the float drops down it completes the circuit activating the alarm.

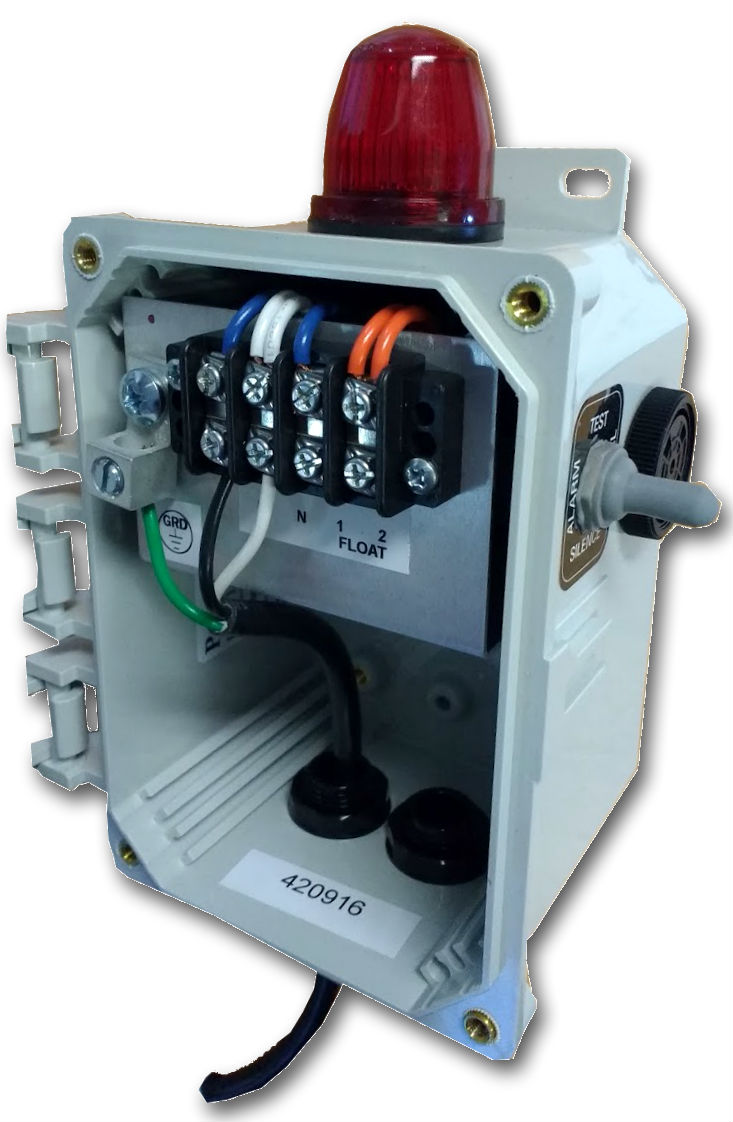

These alarms can be activated with standard single level float switches or made to order multi level float switches. The float switches come in different materials and sizes to adapt to almost any tank. The alarms are offered in various different voltages and are available with audible, visual, or both audible and visual indication.